Printing Area

Printing area of Hercules is big enough for tasks of the most users. Required build volume for 8 of 10 printed models is not more than 8.5 liters. If you need more - Hercules Strong is for you. Its build volume is equal 36 liters. It is enough even for super big models. Hercules Strong is so large that we shot an incredible video about it.

Let us talk about Printing Area and build volume where an item is printed. You could take no notice of its design features choosing a 3D printer (many people act this way).

But you are not like them, right? Of course, printing area and build volume are important. So, let us take a good look at the important things we stuffed printers Hercules.

But you are not like them, right? Of course, printing area and build volume are important. So, let us take a good look at the important things we stuffed printers Hercules.

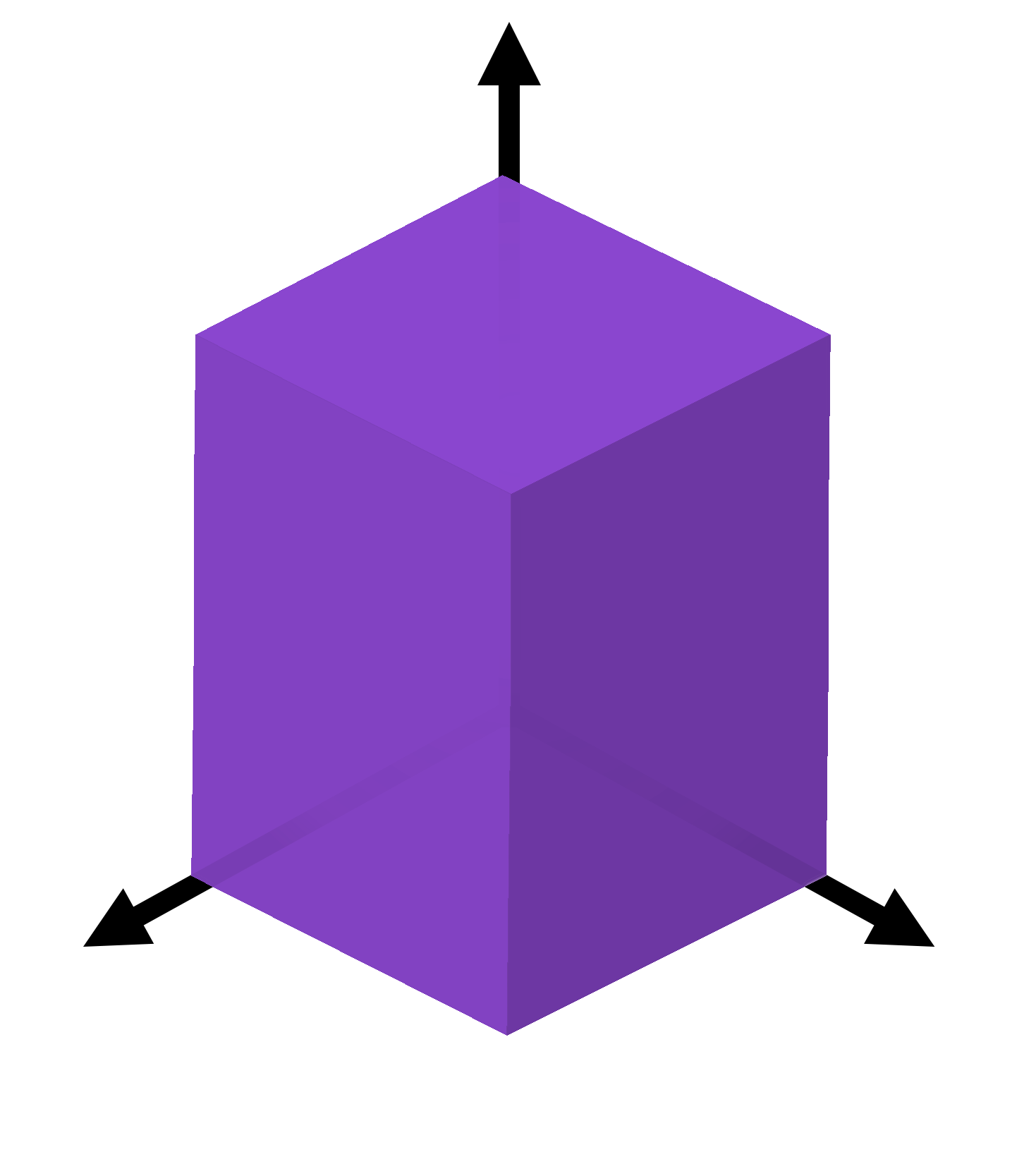

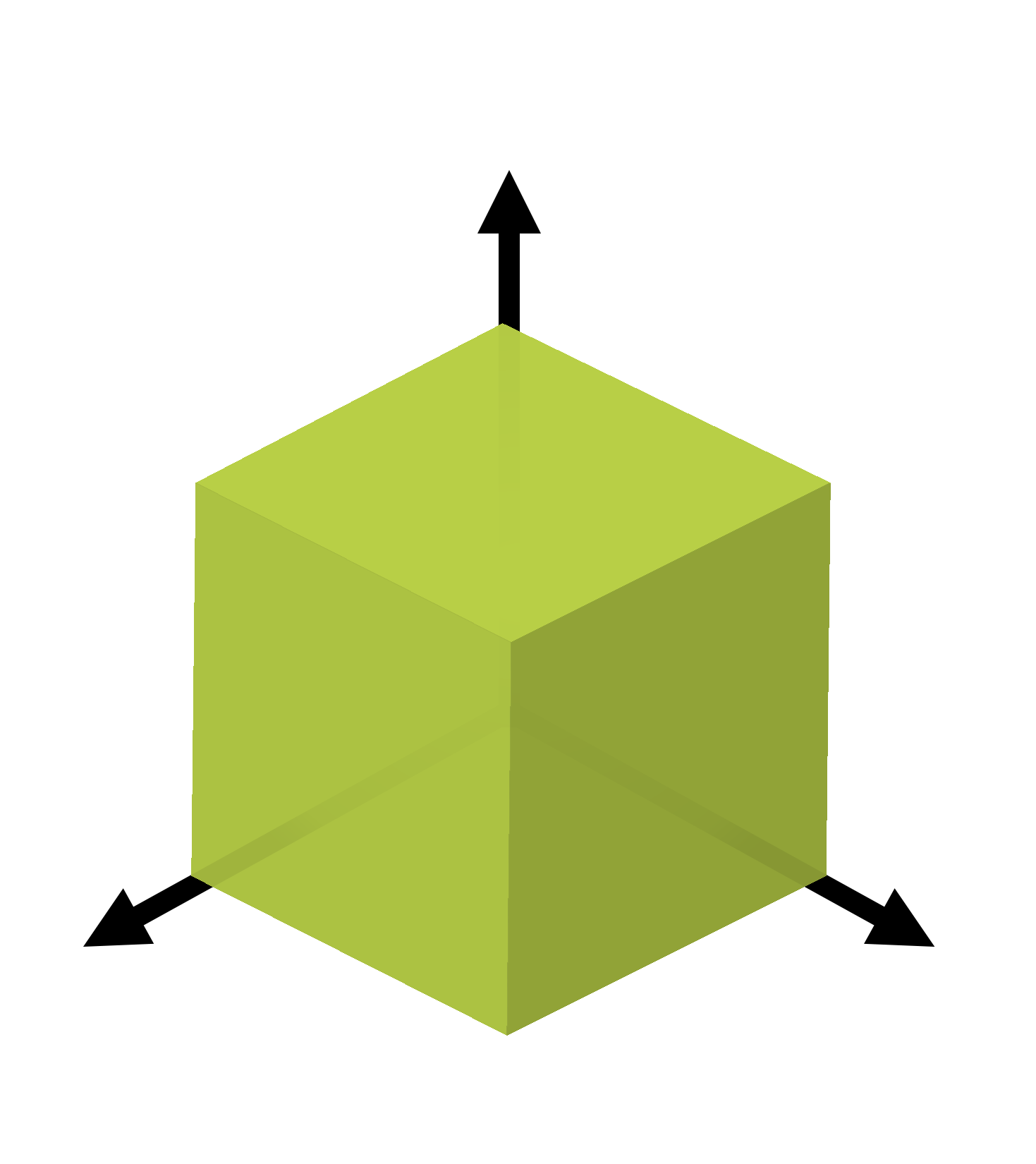

Sizes of build volume

Closed working area provides uniform temperature in the printing area. It is especially important for some materials like ABS or NYLON, because if a printed part gets cold on one side and is heated on the other, internal stresses of material occur. Such stresses wrap and deform the part.

With open working area it is impossible to print an item of NYLON with diameter more than 130 mm.

With open working area it is impossible to print an item of NYLON with diameter more than 130 mm.

Closed working area

The table on which an item is printed shifts up and down along two guide shafts. The bigger they are in diameter, the less vibration and backlashes occur.

Solid heavy shafts

The bigger is diameter of a shaft, the wider is the contact area between the shaft and a linear bearing. It provides the required stiffness of the construction.

All these aspects effect on quality of printed item: each layer lies down onto a previous one more evenly. All our printers have 16 mm diameter shaft. It is magnifical in comparison with previous models of Hercules, which had shafts two times thinner.

Recently printed item should first cool down before you take it from glass of the table. If you have no time for your printer to stand idle, you can just take out the glass off the table with the printed item on it. You can continue printing.

Removable glass of working area

Moreover, it is very ergonomic; just try to take out the printed item carefully off the table within the enclosure of the printer, so you will estimate the removable glass. So you will realize that removable glass is a "gift of God"

If you pay attention on trifles (but pleasant trifles), we would like to mention LED lighting. It smoothly lights the working area. So you can monitor printing process without opening the door.

Icing on the cake

3 point calibration of the table, instead of 4 point. Therefore, it should be so, because we need only 3 points to define a plane, especially, for such small sizes.

Summary:

Two different printers with different working area, choose one for you task.

1

2

Closed working area for an item to cool down uniformly and not to wrap.

Solid heavy shafts to damp down vibration of the table.

3

Removable glass for nonstop printing.

4

Ligthing for the beauty and monitoring of printing process, intuitive calibration system.

300

mm

300

mm

400

mm

200

mm

200

mm

210

mm

Open printing area

Closed working area

— heated air

Balanced running

Vibration and backlashes

16

shafts of all printers

mm

Связь 1

Разделение

Между блоками

Связь 2

5

Связь 1

40 px

Разделение

75 px

Между блоками

12 px

Связь 2

25 px

Extruder UniHot

Hercules in movie making. How it helps to save money