Extruder Hercules UniHot

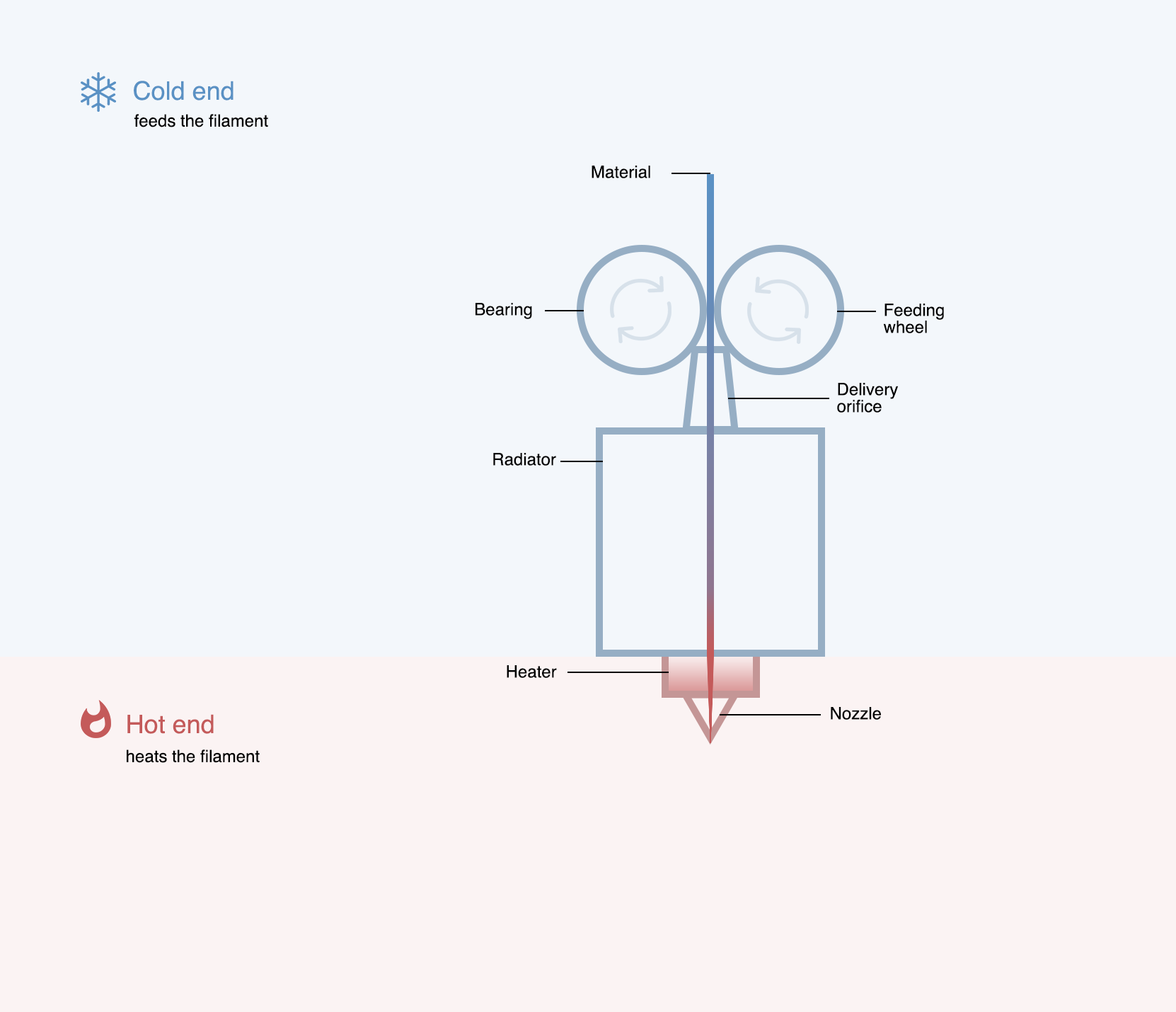

To melt the material the cold end unit takes it and feeds to the hot end unit, which is located below. Nevertheless, materials can be various, for example, PLA- plastic and rubber have different properties. That is why adjustment of pressing force for fed material is necessary to achieve perfect printing process for any material. For this purpose, the print head has the pressing force adjustment system.

Another advantage of UniHot is a delivery orifice, which is located as close to the rolls as possible. It helps to avoid jamming of the filament and allows high-speed printing of flexible materials.

The Hercules UniHot can operate with any material from PLA to CARBON. Just choose one for your task. Main point is that high quality filament should be used: cheap filament can have air and foreign deposits in it.

Everything in the 3D printer is important. But the most important part of 3D printer is a print head. Main specifications of the 3D printer such as productivity, materials used for printing etc. depend on it.

That is why we have designed the print head Hercules UniHot. Further, we tell you about UniHot: its features, advantages, and how it effects on printing.

That is why we have designed the print head Hercules UniHot. Further, we tell you about UniHot: its features, advantages, and how it effects on printing.

Cold end

By designing of the hot end unit the aim was to reduce glass transition area. It is area where the plastic liquates. The shorter the area is - the faster the printing process of flexible materials. After we had reduced the area, we achieved stable speed for printing of flexible materials up to 70mm/s. It is 2.5 times faster than any analogs of the printer.

Hot end

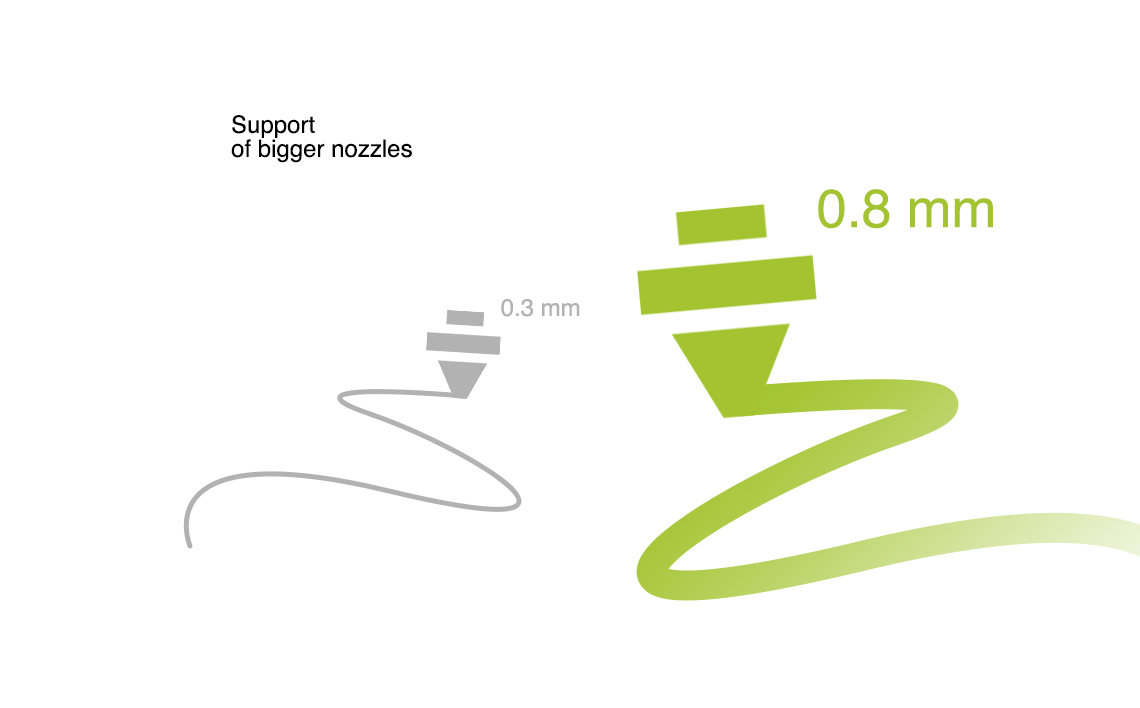

A bigger nozzle allows covering the surface widely and filling up the model with plastic after less number of passes. A 0.8 mm nozzle prints a part two times faster than 0.3 mm nozzle.

Main feature of the UniHot is a cooling system. We located two fans on each side of the extruder to provide uniform cooling of a printed part. It is especially important for PLA plastic, because by printing of PLA the last layer should harden, before a new one will be extruded onto it.

External design

The print head consist of two units: cold end, which feeds filament; hot end, which heats the filament.

To speed up printing process more we added bigger nozzles. You can use nozzles from 0.2 to 1.0 mm. It is easy to change a nozzle – just unscrew it by hand.

Связь 1

40 px

Разделение

75 px

Между блоками

12 px

Связь 2

25 px

The uniform cooling of a printed part

What makes Hercules so high accurate?

Hercules in movie making. How it helps to save money

Связь 1

40 px

Разделение

75 px

Между блоками

12 px

Связь 2

25 px