What makes Hercules so high accurate?

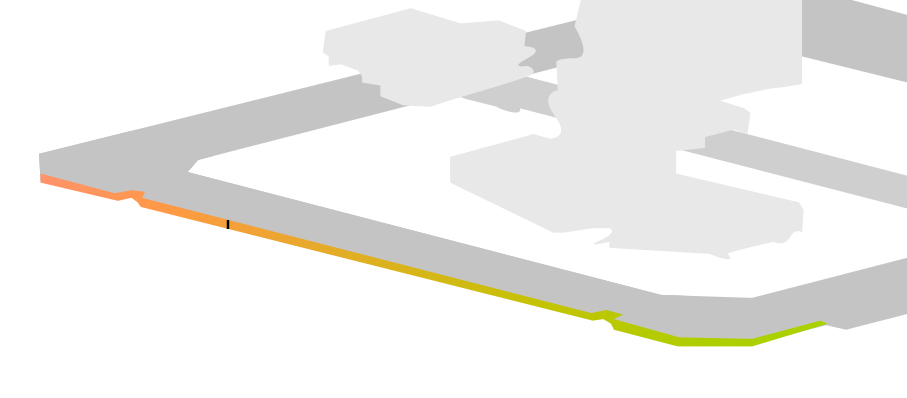

Steel sheet 3 mm

Hard and smooth. What else is there to add?

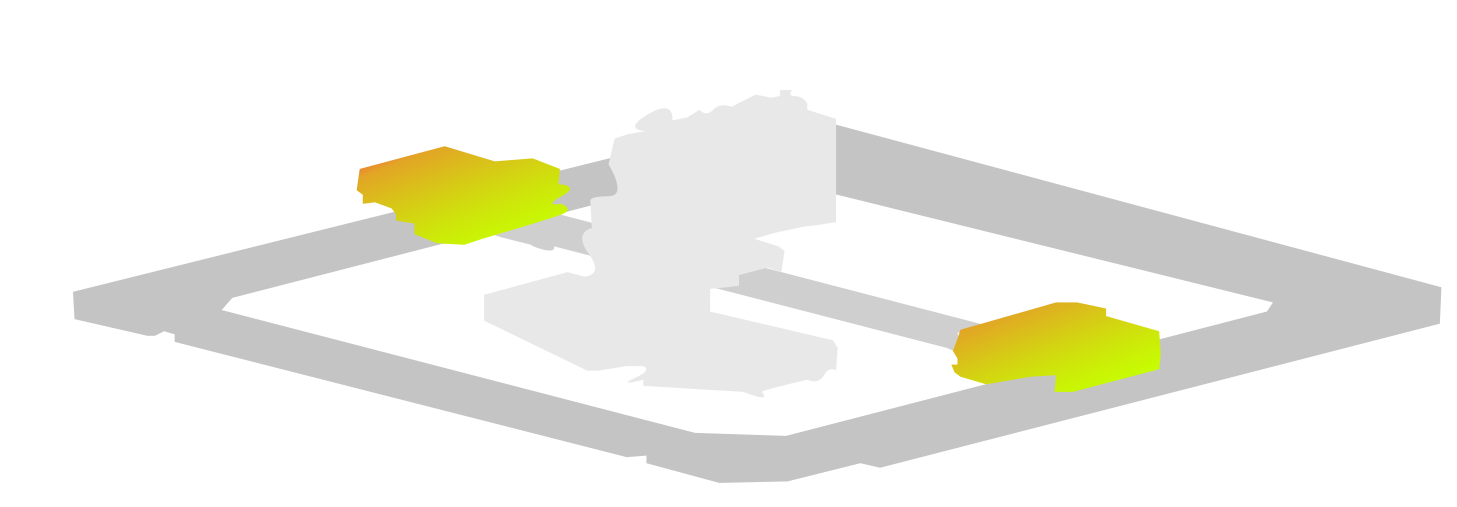

Milled carriages

Often carriages are made of bent or die-casted aluminum. Sometimes carriages are simply printed from plastic. Such technologies allow to make cheap but not strong enough carriages. They can be easily bent by simply moving the print head with your hand

But we are talking about positioning accuracy, to save on materials/cut down expenses is a bad idea.

Therefore, Hercules carriages are made of milled aluminum - they are cut from a single bar of metal. This ensures their stability and durability; only Jason Stethem can bend the whole carriage body with an inaccurate movement.

But we are talking about positioning accuracy, to save on materials/cut down expenses is a bad idea.

Therefore, Hercules carriages are made of milled aluminum - they are cut from a single bar of metal. This ensures their stability and durability; only Jason Stethem can bend the whole carriage body with an inaccurate movement.

Installation on a milled template

When the kinematics plate is assembled together, the most important thing is to observe the right angle between the X and Y axes. If this angle is at least a couple degrees off, each print will be off exactly by this measure as well.

Sometimes the angle is offset by a fraction of a degree and this may not be noticeable to the eye. But if you print master models or other models where exceptional accuracy is needed, this is critical, the print will be failed.

Therefore, we install components on the kinematic board using milled templates. There is not a single millimeter gap between the parts and the template, which means all the parts are in place with great precision and there is a right angle between the axes.

Sometimes the angle is offset by a fraction of a degree and this may not be noticeable to the eye. But if you print master models or other models where exceptional accuracy is needed, this is critical, the print will be failed.

Therefore, we install components on the kinematic board using milled templates. There is not a single millimeter gap between the parts and the template, which means all the parts are in place with great precision and there is a right angle between the axes.

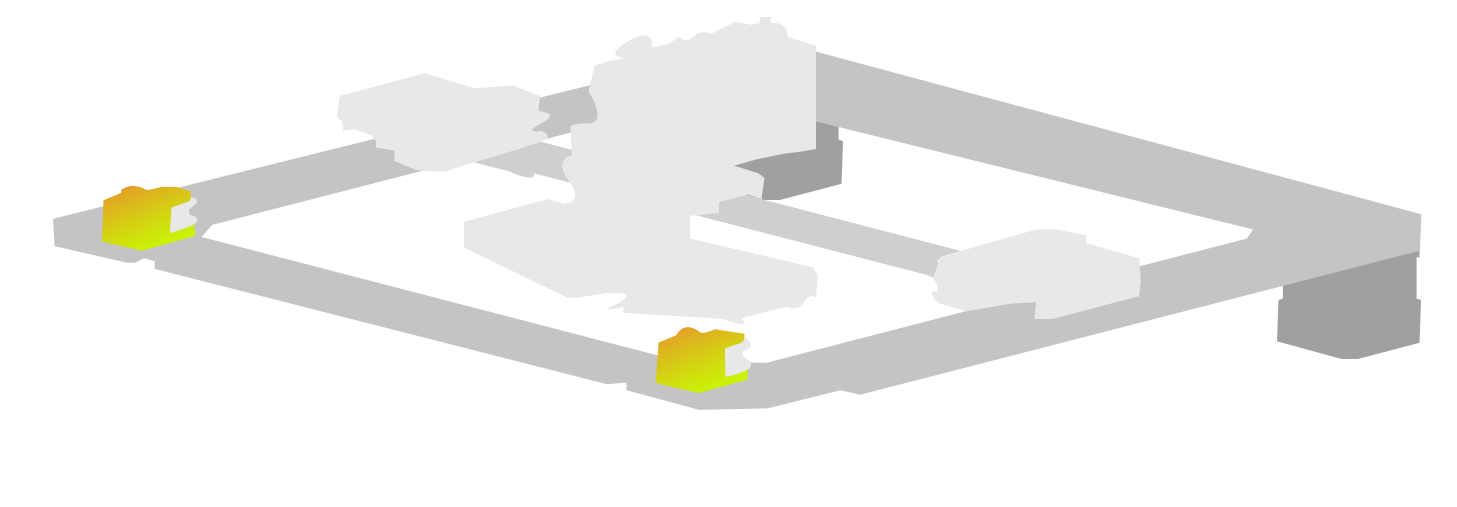

Milled mountings of counter rolls

As you may notice, we mill everything. Including mounting's counter rolls. These ones stand in front of the motor and hold the belt on the other side.

In bad examples of printers, we will see how the rollers can be simply bolted with a conventional screw. Others print plastic or use bent metal cases. We already know the drawbacks of bent metal ones from the previous topic.

If you use these methods for fastening of rollers, then over time, they will warp and the belt will start to rub off against the roller skirt.

In our case, skewed rollers are more of an exception to the rule. Milling is our everything.

In bad examples of printers, we will see how the rollers can be simply bolted with a conventional screw. Others print plastic or use bent metal cases. We already know the drawbacks of bent metal ones from the previous topic.

If you use these methods for fastening of rollers, then over time, they will warp and the belt will start to rub off against the roller skirt.

In our case, skewed rollers are more of an exception to the rule. Milling is our everything.

Kevlar cord in a belt

Since we are talking about a kinematic plate, we will tell you an important feature of the belts that are located on this plate. We use Kevlar cord belts. So what?

The fact is that the Kevlar solders with rubber much better than metal, and therefore has longer lifetime. Metal cord quickly sticks off the rubber belt and begins to stretch and become useless.

The fact is that the Kevlar solders with rubber much better than metal, and therefore has longer lifetime. Metal cord quickly sticks off the rubber belt and begins to stretch and become useless.

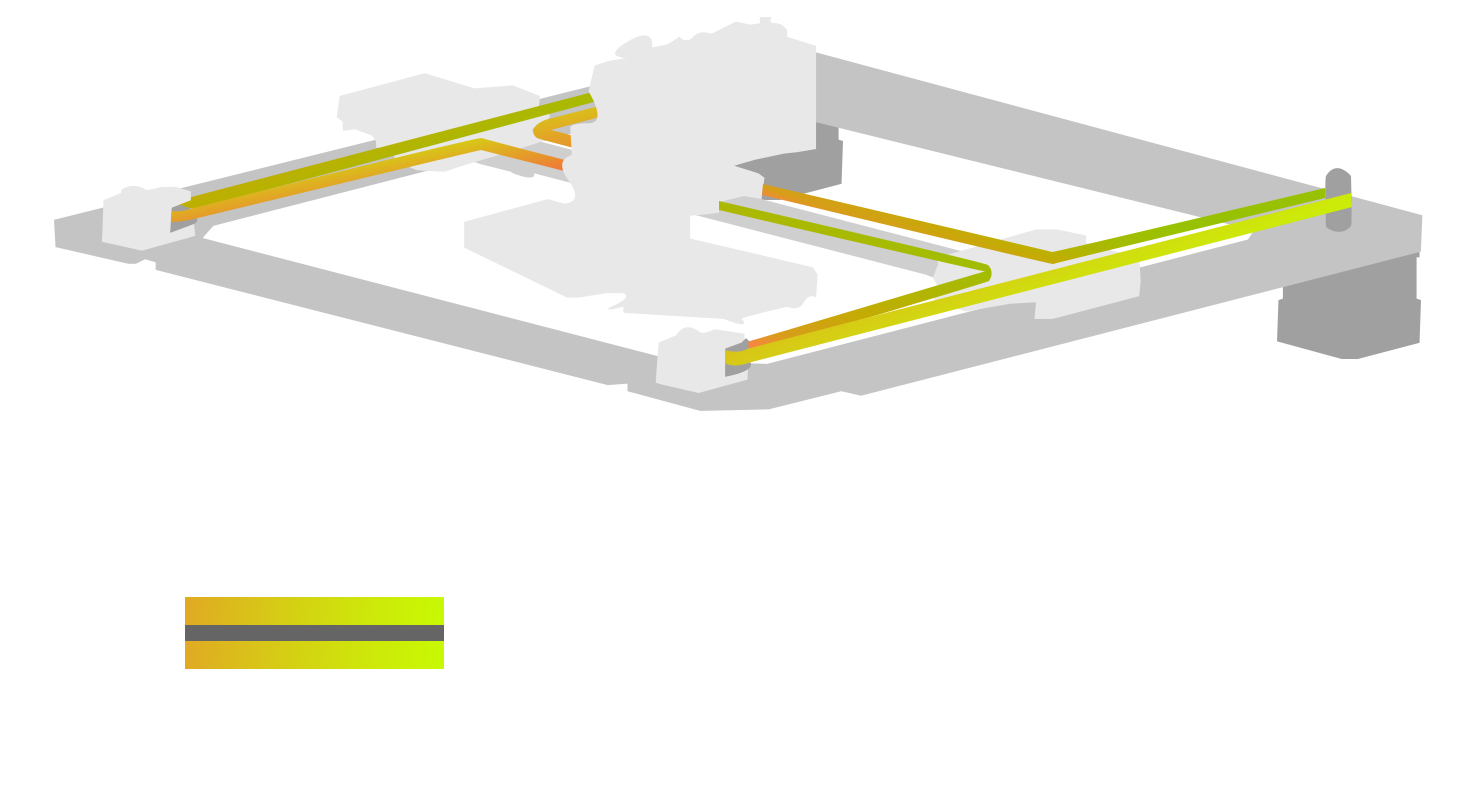

Today, we will focus on the kinematics plate of our printers. This is an important part of the printer (actually, like all the others).

That is why it is important:

That is why it is important:

Kinematics plate

The kinematics plate and everything connected to it is responsible for the accuracy of the positioning of the print head. If it is made reliably and firmly, then the motors will work as accurately as possible.

Such accuracy is especially important for small items that are printed in a thin layer. Any backlash or deflection in kinematics will mean that the model can be thrown out. Therefore, all solutions that are applied to the kinematic plate should ensure its stability

Such accuracy is especially important for small items that are printed in a thin layer. Any backlash or deflection in kinematics will mean that the model can be thrown out. Therefore, all solutions that are applied to the kinematic plate should ensure its stability

1

carriage

Second

carriage

First

motor

2

motor

roll

2

roll

1

Rubber coated kevlar

thickness

3

mm

1

2

Связь 1

40 px

Разделение

75 px

Между блоками

12 px

Связь 2

25 px

Electronics

How can support service help me?

???????????????

???????????????

???????????????