How to print a motorbike, which can be driven?

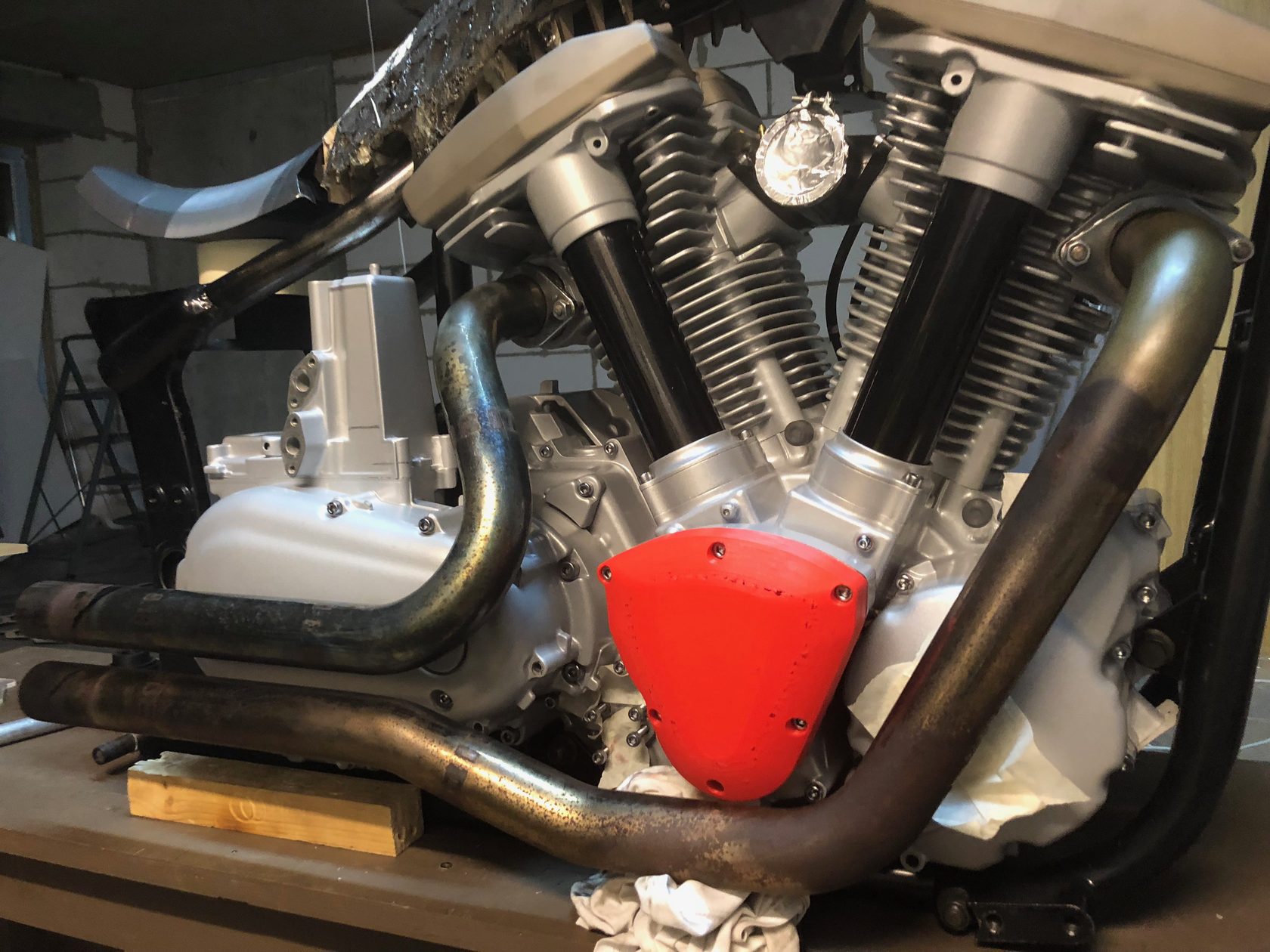

I am making the custom bike for the Customizing Championship in Russia, and you can note that it is in working condition and has documents required for use on public roads.

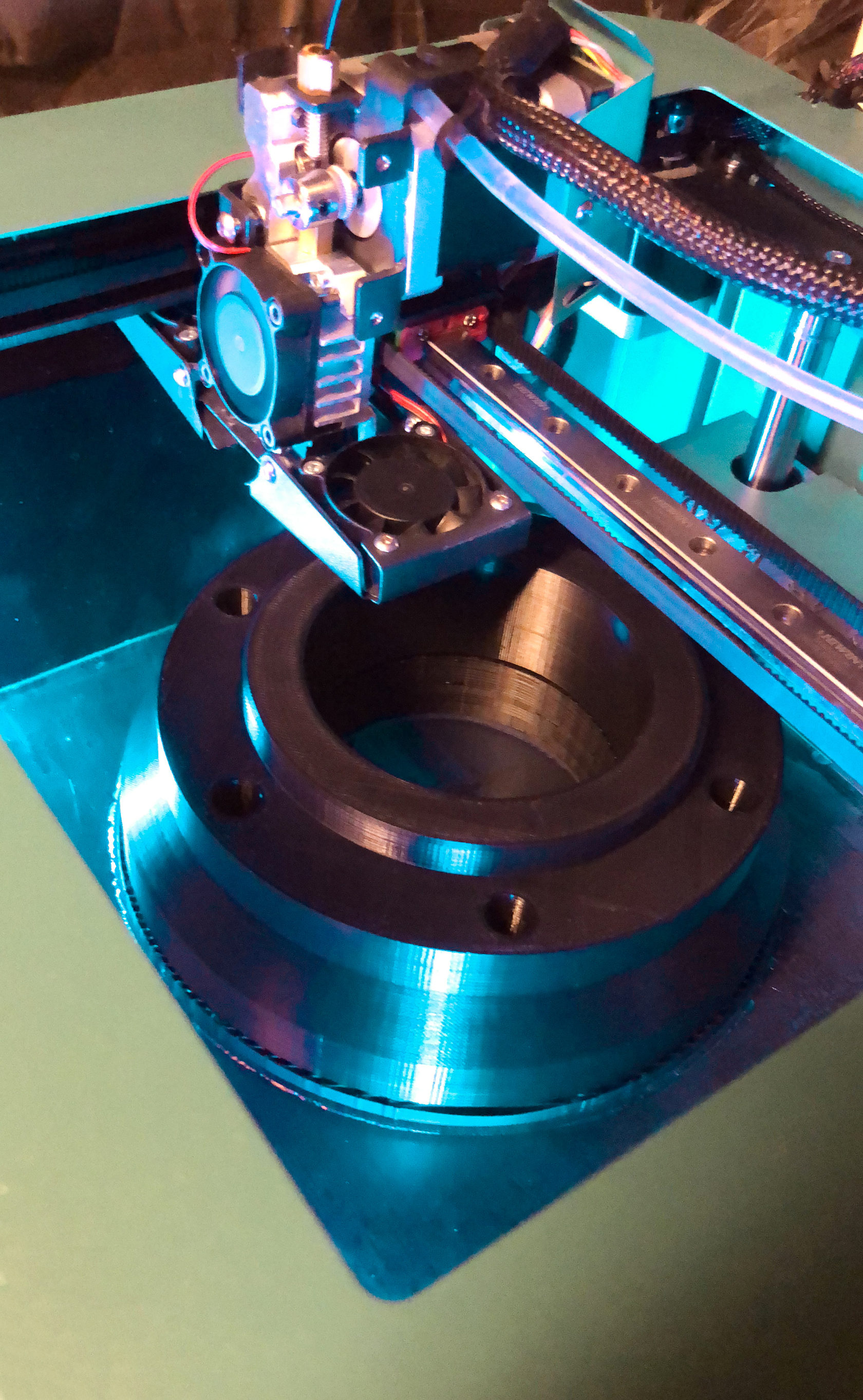

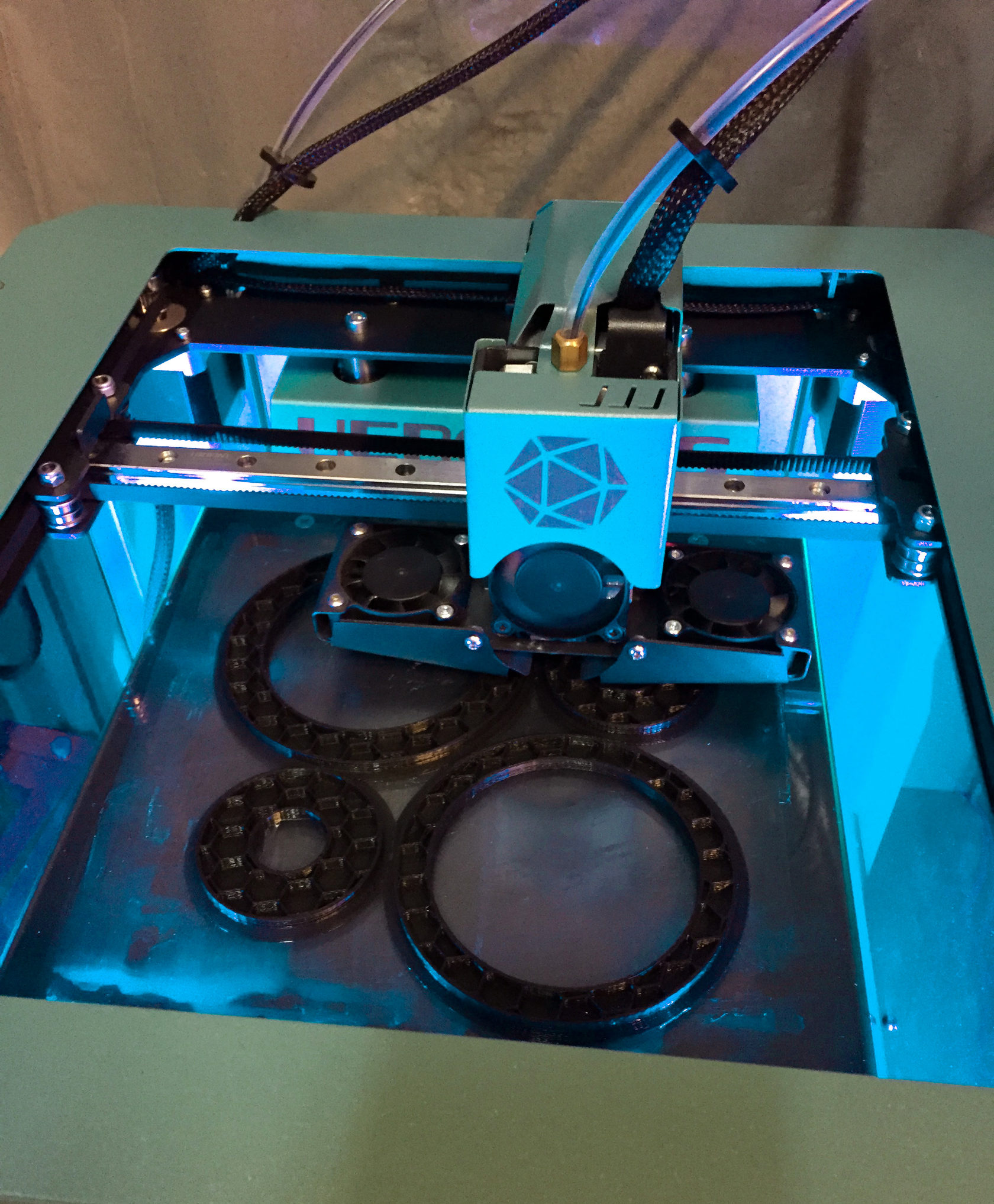

Radik uses 3D printer Hercules to create such a motorbike.

Radik

This is Radik Gubaidullin

He is a founder of "Vizuit lab". He is engaged in motorbike customizing. Now he is creating the unique motorbike.

Render of completed motorbike

Two reasons why I need 3D printer:

Radik

To prototype and test parts before final producing it of metal.

To print parts which do not work under the load: enclosures for electronics, decorative covers, and cover plates etc.

To print parts which do not work under the load: enclosures for electronics, decorative covers, and cover plates etc.

1

2

Usually prototypes are made manually of carbon fiber with using epoxide resin. In this way, nothing to say about a lack of cleanness on your workplace; and also considering the fact that this method requires plenty of time and the resin emits toxic vapors; it will effect on your health, cause headache and dizziness.

Therefore, it is better to apply manual labor and talent of a sculptor in a software of 3D modeling and put a precise tool on to produce it.

Any handmade part tends to be less accurate than one produced by a machine. It is matter of course that you will never produce anything yourself with micron accuracy, but Hercules can.

Therefore, it is better to apply manual labor and talent of a sculptor in a software of 3D modeling and put a precise tool on to produce it.

Any handmade part tends to be less accurate than one produced by a machine. It is matter of course that you will never produce anything yourself with micron accuracy, but Hercules can.

40% parts of my motorbike is made of plastic and printed on Hercules. I am the first one who implemented such a project. I will show it on exhibition IMIS 2019.

Radik

The process of printing parts for the motorbike on Hercules.

Radik's conclusion:

Materials for 3D printing develop very fast; their strength property and temperature range of working get higher. That is why, I am sure, that customizers will use 3D printing the way I do, because it helps to save sources, one of those is time.

Radik

Photos of workplace

| Customizer

| Customizer

| Customizer

| Customizer

Связь 1

40 px

Разделение

75 px

Между блоками

12 px

Связь 2

25 px

Hercules in movie making. How it helps to save money

Связь 1

40 px

Разделение

75 px

Между блоками

12 px

Связь 2

25 px

Printing Area

Вернуться

Cast (PMMA)

€

2990

Цвет

Толщина и вес

Особый материал на основе полиметилметакрилата с добавлением специальных пластификаторов.

Материал подготовлен специально для печати объектов, применяемых в литье по выжигаемым моделям.

Массовая доля золы менее, чем 0,01% от массы напечатанного объекта при выжигании его на ~405°С. Таким образом, этот материал обладает предельно низкой зольностью, что делает его идеальным материалам для создания выжигаемых мастер моделей.

Печать материалом CAST немногим сложнее, чем печатать ABS пластиком, при должной сноровке можно добиваться потрясающих результатов.

Материал подготовлен специально для печати объектов, применяемых в литье по выжигаемым моделям.

Массовая доля золы менее, чем 0,01% от массы напечатанного объекта при выжигании его на ~405°С. Таким образом, этот материал обладает предельно низкой зольностью, что делает его идеальным материалам для создания выжигаемых мастер моделей.

Печать материалом CAST немногим сложнее, чем печатать ABS пластиком, при должной сноровке можно добиваться потрясающих результатов.